How is CBD Oil Made?

Summarize

CBD processing from field to oil bottle is a system developed to extract a compound from the industrial hemp plant. Industrial hemp is legally authorized by the Hemp Farming Act of 2018. It is the cannabis sativa L plant that was specially developed to have no more than 0.3% THC, the psychoactive cannabinoid. Each CBD oil producer has developed a proprietary production process for their products, but there are some basic steps that all producers follow.

TL;DR (Too Long; Didn’t Read):

CBD oil production is a science in that CBD producers utilize specific steps that begin with choosing quality hemp plant material to select a CBD extraction process. The preferred CBD processing system is determined by the desired CBD spectrum, which could be full spectrum CBD, broad spectrum CBD, or isolate CBD. The precise CBD oil-making process includes blending a carrier oil like MCT or olive oil with the crude CBD and adding flavoring or other ingredients like minerals and botanicals.

Table of Contents

How is CBD Oil Made: A Step-By-Step Overview

There is a basic process each CBD producer follows to extract CBD (cannabidiol) and turn the extract into CBD oil. The commercial CBD oil-making process is critical to the quality of the final product. High-quality CBD product contents match the product label, proven by third-party lab testing with results reported on an accessible Certificate of Analysis.

Following are the steps that explain how CBD oil is made from hemp.

| Grow a Hemp | Choose CBD Spectrum | Select an Extraction Method | Manufacture CBD Oil | Blend with Carrier Oil | Add Ingredients |

Step 1: Obtain a Hemp Source

Some companies plant and harvest their hemp plants on private farms, while other producers purchase hemp plants from U.S. or European farmers. Many CBD producers use the hemp plant’s flowers and nearby leaves or only flowers to obtain CBD because these plant parts contain the highest CBD content, plus other compounds like flavonoids and terpenes. When harvested at the end of the growing season, the hemp plant produces more flower resin to support pollination. This is the ideal time to obtain the resin containing CBD and other cannabinoids because they are at their peak amount.

However, whole-plant CBD oil is also made, which sounds exactly like what it is. The whole plant is used for obtaining CBD. However, the hemp plant colas or buds and the leaves immediately surrounding them have the highest CBD. The rest of the plant mainly offers botanical material that may provide benefits like fiber, protein and minerals.

After harvesting, the stems and branches are removed from the colas and leaves and the remaining plant material is hung to dry. Once dry, the plant material is trimmed again, and the buds are dried. This is the curing process in which the buds are dried to achieve the desired moisture content so they can be stored until the CBD extraction process begins.

Step 2: Decide the Type of CBD Spectrum Desired

There are three CBD spectrums available in CBD oil. The choice of CBD spectrum to produce influences the extraction process.

Full Spectrum CBD

Full spectrum CBD oil contains CBD and other cannabinoids, including THC. It also contains terpenes and flavonoids.

Broad Spectrum CBD

Broad spectrum CBD contains CBD and other cannabinoids except for THC, which is removed during processing. It also contains terpenes and flavonoids.

Isolate CBD

Isolate CBD is only CBD. All other compounds are removed during the production process.

Step 3: Select a CBD Extraction Method

Each CBD brand knows how to extract CBD in a way that supports the brand’s philosophy. For example, some companies do not want to use a solvent during extraction. CBD must be extracted from the plant material, and here are two main CBD extraction processes used today.

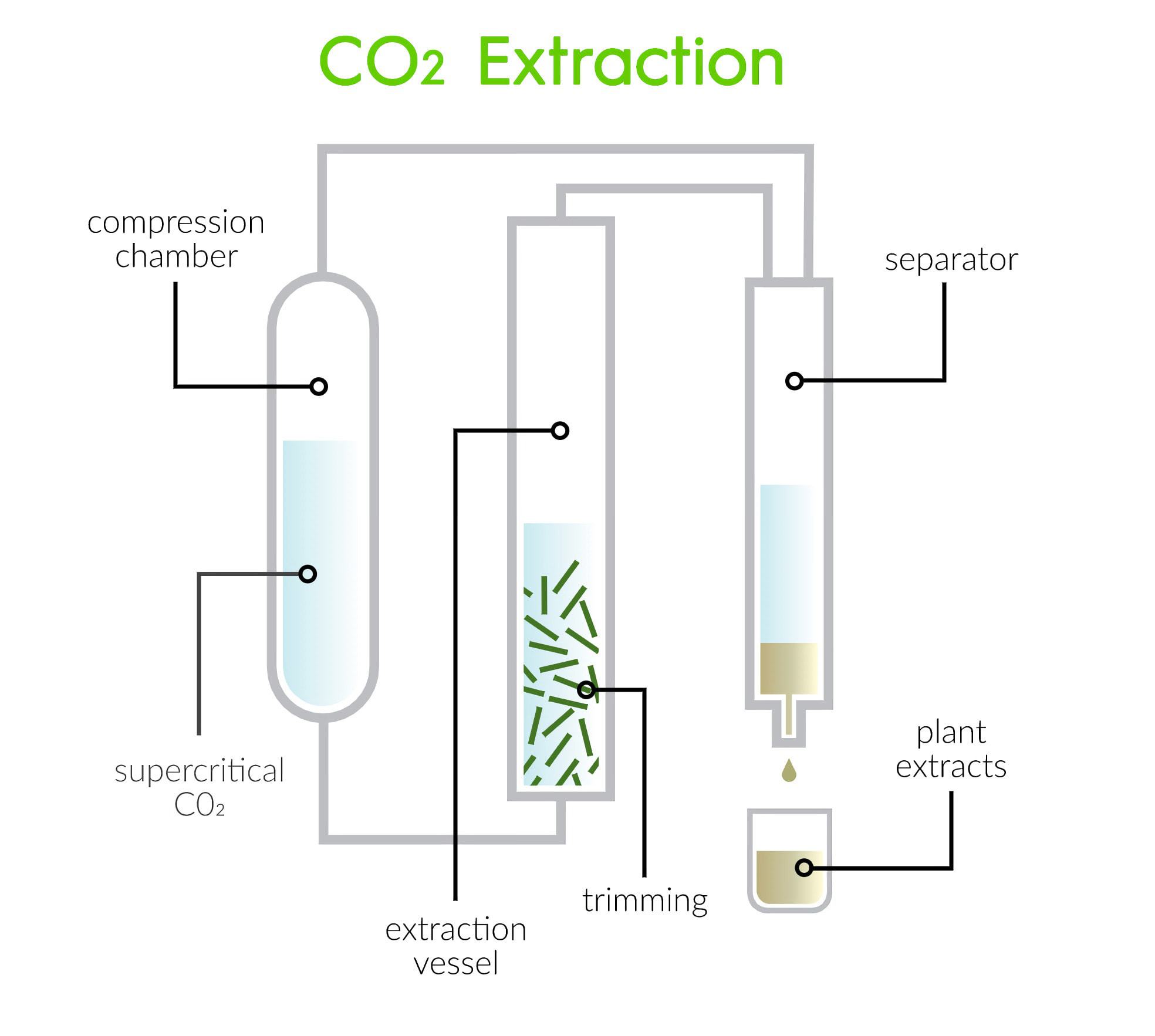

CO2 Extraction

The supercritical CO2 extraction process uses carbon dioxide to strip the hemp plant material of cannabinoids, flavonoids and terpenes. Carbon dioxide gas is placed under extreme pressure to become a liquid CO2. The liquid CO2 is kept under pressure and placed on the plant matter, and the plant compounds leach into the liquid CO2. High pressure and a low temperature are used to preserve the natural state of the compounds. The pressure is then released, and the liquid CO2 returns to carbon dioxide gas, leaving the extracted material. Getting the CO2 flow rate and pressure right is critical to obtaining the best CBD and THC amounts. This process can produce some of the finest quality hemp plant extracts.

Ethanol Extraction

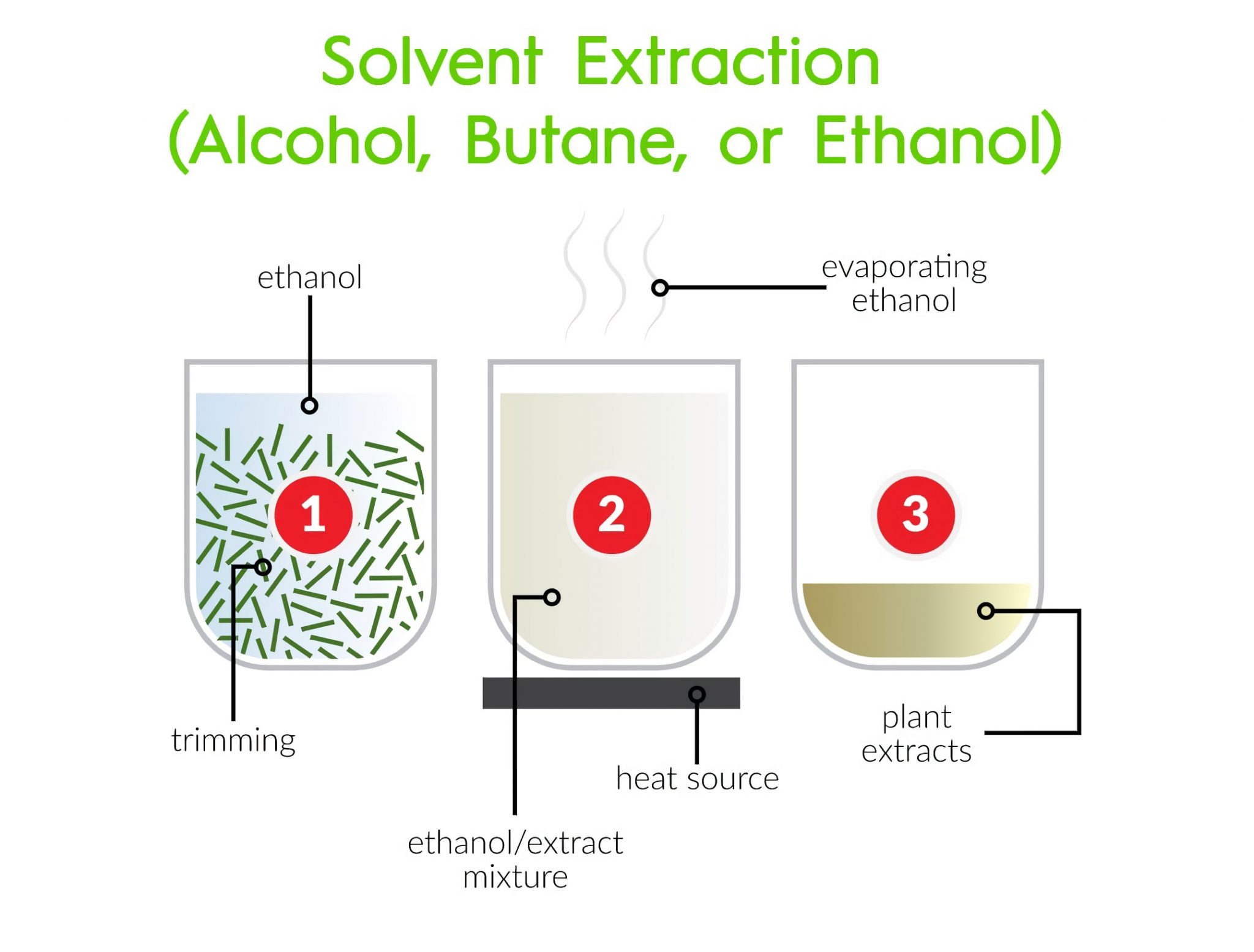

The hydrocarbon or ethanol extraction method uses a solvent to separate CBD and other compounds from the hemp plant. It is a simpler, effective extraction process that can be done under cold or warm production conditions. Some consumers choose CBD oil made with CO2 extraction to avoid the chance of solvent material being in the CBD oil.

However, high-quality producers will remove the solvent by adding another step after decarboxylation (release of the CO2) called distillation. This process isolates specific compounds like CBD and THC, leaving a small amount of terpenes and other compounds. The process heats the CBD oil to a vapor cooled down in a condenser to become a liquid residue. The residue is collected into different fractions, with two being the CBD and THC fractions.

Organic sugarcane ethanol can also be used. Ethanol is combined with the hemp plant material, and the concoction is heated in a water bath. The ethanol evaporates and leaves behind the extracted compounds.

Step 4: Manufacture CBD Oil

CBD oil production can begin once the CBD spectrum and extraction process are determined.

Full Spectrum CBD Production

Full spectrum is made by stripping out all of the compounds in the hemp plant flowers and leaves. If using only the dried and cured hemp plant flowers, the CBD oil producer must convert the CBD precursor called CBDA into CBD. This is done through the process called decarboxylation.

If using the entire hemp plant, a similar process is used, but of course, the process is less labor intensive since the flowers and leaves are not separated from the plant.

Broad Spectrum CBD Production

Broad spectrum CBD oil follows the same process steps as full spectrum CBD extraction, with one exception. The THC cannabinoids are removed as much as possible. Many broad spectrum CBD oil products are called THC-free or as having a trace amount of THC.

To know how to make CBD oil without THC, you should understand the basics of chromatography. The chromatography method is commonly used to remove THC from full-spectrum CBD extract. This method isolates the THC while preserving all other major and minor cannabinoids. The crude CBD oil is added to a filter material like silica. A solvent is then pumped in, and the difference in CBD and THC chemical makeup separates them. Another method allows THC-A to degrade over time into CBN, accelerating the process with light, heat and pressure. Of course, this takes longer than removing THC with chromatography, but no solvent is used.

Isolate CBD Production

This is the most processed form of CBD because all cannabinoids, terpenes and flavonoids are removed from the hemp plant extract except for CBD. The CBD isolate is made in steps that begin with the extraction process followed by winterization, in which the fats, chlorophyll and waxes are removed from the extract. The extract is cooled to sub-zero temperatures by using a solvent. The fats, waxes and chlorophyll coagulate or separate and are easily filtered out with a vacuum pump. The decarboxylation process is completed to remove any CO2 and carboxylic acid from the cannabinoids, turning CBDa into CBD. The decarbed extract goes through the distillation process, and the final step is usually crystallization. In crystallization, CBD oil is turned into crystals. The crystals can be sold as crystals or ground into a CBD isolate powder.

Step 5: Blend CBD Oil with Carrier Oil

CBD is fat soluble, so it is blended with a carrier oil to assist the body’s absorption of CBD. Fat-soluble substances do not enter the bloodstream directly. They are converted to micelles by enzymes in the digestive tract. Micelles are small droplets able to enter fatty lymph tissues. The micelles travel through the lymph system and eventually enter the bloodstream above the heart.

The most popular carrier oil is MCT oil. MCT is the acronym for medium-chain triglycerides and has a high concentration of fat-soluble molecules. The two main types of MCT oil are coconut oil and palm oil. However, palm oil is falling out of use because palm oil production leads to rainforest deforestation. Most CBD oil brands use coconut oil. If the label says fractionated coconut oil is an ingredient, the oil has more liquid than solid material.

Some other carrier oils include:

- Olive oil

- Grape seed oil

- Sesame oil

- Avocado oil

- Hemp seed oil

Every type of carrier oil added is done so to increase the bioavailability of CBD and other phytochemicals. There are also health benefits associated with the carrier oils, so high-quality CBD producers choose a carrier oil based on its potential impact on well-being.

Step 6: Add Additional Ingredients to CBD Oil

When shopping for CBD oil, you will quickly find many flavors and products with ingredients like herbs, vitamins and minerals. Flavoring and other ingredients are blended with CBD and carrier oil as a final production step.

CBD Product Testing a Critical Step

Reputable CBD oil makers test their products at each step of the production process to ensure quality is maintained. An equally important step quality CBD brands take before selling CBD oil is having an accredited third-party laboratory test a sample from each CBD product batch and issue a Certificate of Analysis (COA). The lab testing ensures that the product does not contain unwanted compounds like heavy metals and pesticides, microbials and solvents and that the CBD concentration is accurate. The lab also identifies detectable cannabinoids in the CBD oil, like THC and CBG.

The preceding description covers the basics of CBD oil production. СBD oil-making process is a science requiring the proper knowledge and equipment, high-quality hemp plant material, proprietorial formulations and careful adherence to quality. The products you find on CBD.market have been carefully formulated and produced to ensure customers get the most benefits from the industrial hemp plant’s extracts.

Sources

- https://www.congress.gov/bill/115th-congress/house-bill/5485

- https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7272408/

- https://www.ncbi.nlm.nih.gov/pmc/articles/PMC8290527/

- https://www.ncbi.nlm.nih.gov/pmc/articles/PMC8150740/

- https://hempindustrydaily.com/remove-thc-or-degrade-it-cannabis-extractors-say-theres-room-for-both/

- https://precisionextraction.com/2020/09/how-to-make-cbd-isolate/

Share this post

0